A-Frame Outbuilding Construction Drafts 10x24 : Master Tricks For Constructing A Shed Speedily

Put a level across both sets of wall plates to ensure the walls are level in all directions. The potting shed includes three aluminum-clad, double-hung windows. Drill a hole in the ledger at each mark. They are put in specifically to hold up a subfloor that is then used as the attachment point for hardwood flooring, carpeting and even vinyl or ceramic tiles. A few nails or screws at each end would join two panels together. If you have trouble finding solid blocks at a home center or lumberyard, visit a masonry supplier. Complete the job by building door out of cedar, and nailing on the window trim and corner boards.

Using 2-by-4-inch boards creates conventional wall framing. Work with attention and plan everything from very beginning, if you want to get the job done as a professional from the very first attempt. Typically, one end of the joists rests on an exterior foundation sill, and opposite end (get more) rests atop a girder. Nail joists in place, then attach the outer rim trestles to front and back of floor frame. Now craft the 'noggins' from more stud timber. Each rafter has a notch that fits over the side beam. Leave enough room at the bottom to cover the wooden trims. The four planks should form a box at this point.

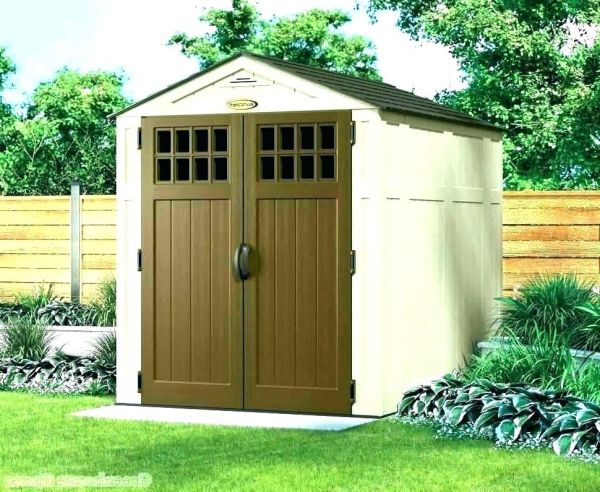

Cut 2 x 4 stock to length for wall studs and window and door jack studs. The top doorjamb should rest against the wide trim board. Arch-top windows and a custom door give this outbuilding a high-quality look that belies its low cost and simple construction. Find the center of each window and door opening. Use two hinges to secure door into place. Doing calculations could be extremely confusing unless you are an expert in the field. Instead, stand the framed wall and brace it. Most of these common species are listed on deck span tables along with required information to select proper size.

We had been making shelves and small furniture pieces out of pallets for a couple months and started discussing using pallets as our building material. You could probably source better lumber for less elsewhere. Measure the distance between the walls, then crosscut the long beams and bolt them to the posts. Lastly, check and adhere to local codes and ordinances and have all the necessary permits. Assemble frames on a level surface. Use the same chalk line template and process to build the opposite end wall. The double top plates will also add strength to construction. Another option is to install doors on both gable-end walls, so that you'll be able to easily reach items from either end of the shed.

Building it too close to trees, shrubs, fences or other structures would block out sunlight and wind that help keep a outbuilding dry. In addition, fit bottom beam to the posts. In areas with poor drainage or freezing conditions, it's a good idea to dig cement footings down into the soil, with the tops of the footings extending above grade. Leave enough space for a large door opening, as to have a good access to attached shed. Attaching a metal strap to the bottom edge of joist can stabilize a notched joist, increasing the tensile strength of joist. The edge should align with the edge of the outside trusses or in center of the inside trusses.

Each of these styles has their advantage both in design and construction. Small sheds could go on concrete slabs or blocks. Shopping list, cutting list, and the picture do not add up. Make sure that a seam doesn't fall on a middle framing board. Later, they'll be through-bolted for solid support. The off-the-rack alternative to custom flashing is a galvanized drip edge specially made for flat roofs. If you go with the slab, it's a good idea to hire an excavator and mason to have the job done right.